1356 - cab rebuild

Mike, Mitch, Andrew, Scott, Doug — Trying this out as a way we can all communicate. This is a private space; it doesn’t show up in the web page navigation and I also passworded it. It should allow us to post chats, questions, comments, photos, et cetera, where we can all see them and participate. It should also be easier to organize and refer back to than group emails, and also it allows us to keep a record that’s more under our control than say, Facebook.

Doug Shearer, who was the lead on the 1364 restoration and has been working to help us get blueprints, says he'd be happy to join in our conversation and give his "2 cents worth" of advice, which I'm just going to say is worth a lot more than 2 cents and we are really lucky to have him aboard. I have a couple texts from him that I’m going to post here for thoughts and comments; here’s the first:

From Doug, re blueprints, moving cab, restoring to original:

I believe we will get blueprints. I spoke to Ladd Siegfried. He is out of state until March, but has made calls to try to facilitate getting the plans.

Is 1358 cab still there? If so, when you are ready to begin, unbolt it, lift it off the running boards and take it to the people rebuilding it. It will have to be dismantled to get all the steel parts. Take lots of photos and just duplicate parts that make the sides, front and back walls and roof. As they dismantle, they will see all the joinery used to recreate the walls, windows and other pieces to bolt back together for the new cab.

We obtained most of the wood from the dismantled cab and used the plan to figure what pieces went where. Not one piece of original wood was even close to usable due to dry rot, but pieces revealed all the reinforcing rods which were hard to recognize from the plans. We made multiple trips to Pasco to see the 1354cab when we had questions.

I’ll be happy to share photos or specific measurements of parts you may be missing.

The NP used standard plans for the basic structure and I doubt there will be any significant differences in that. The differences will be in little things that might be changed over the years. The electric fuse panel doesn’t show on the plans because they originally had no electricity! Headlight was kerosine. Are your “original” fans going to rebuild back the original Vaulclan Compound” mechanism. Do they want to remove the number boards off the smokebox? Change the front walkway steps to the older style?

At many shoppings minor changes were made. We couldn’t find a reference for the whistle lever placement. The one on 1354 was hanging as the beam that supported it had rotted away. With no reference material our chief mechanical officer placed it where he found it most comfortable on steam engines he had worked in England. Who can argue that placement without documentation.

The cab has to be removed before another is put on. There are 4 main brackets that bolt it on. We put a couple of beams extending through the windows on each side and easily swung it into place. Reverse process and take to shop to document and dismantle.

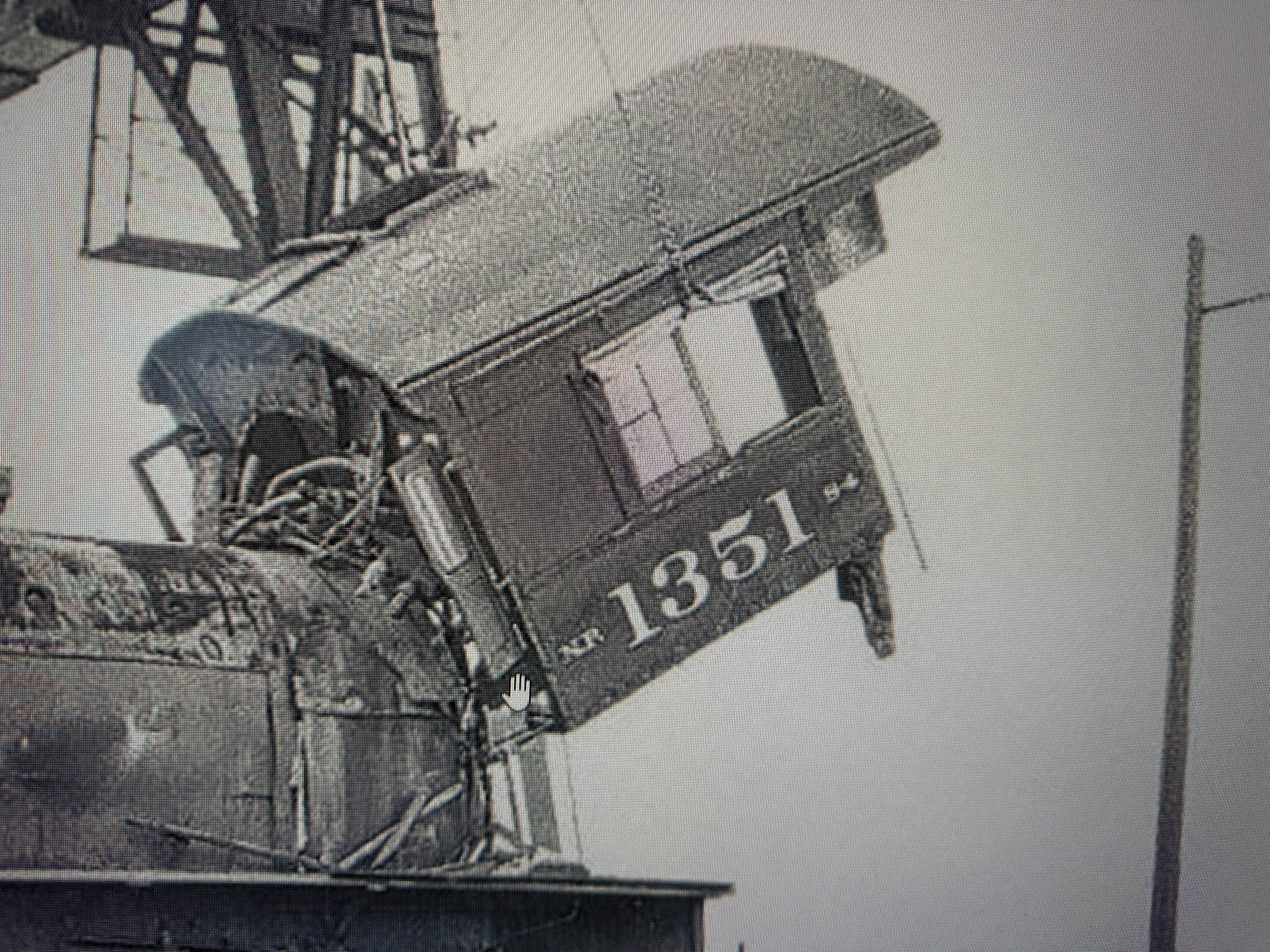

I said beams but had forgotten that we used an old boiler pipe. Initially planned two but it ended up working better to use one at balance point. Everything on plan is in this photo. No location for lights, electrical, door latches, etc.

We fashioned wooden supports for the boiler tubes to distribute load and protect window opening. Originally we had two tubes but moving off and on became easier with just one. Note wrong balance point by NP at scrapping of 1351.

Andrew: Jeannine - rough estimate of labor would be two days onsite with a telehandler (long reach forklift) and a scrap trailer (or construction dumpster) to demo and remove the current cab. Scott can provide estimate here. For rebuild, $5K in lumber and supplies. Mitch mentioned he has a relation that may be able to supply running board replacements, cab flooring lumber.a new rear tender beam.

And for reinstallation 2 days with a telehandler onsite again to lift sections as needed.

Mon 4:39 PM

Jeannine: Scott, really interested in your thoughts. I think Doug's method of cab removal might be somewhat different so I'm reposting it here: "The cab has to be removed before another is put on. There are 4 main brackets that bolt it on. We put a couple of beams extending through the windows on each side and easily swung it into place. Reverse process and take to shop to document and dismantle. I said beams but had forgotten that we used an old boiler pipe. Initially planned two but it ended up working better to use one at balance point. Everything on plan is in this photo. No location for lights, electrical, door latches, etc. We fashioned wooden supports for the boiler tubes to distribute load and protect window opening. Originally we had two tubes but moving off and on became easier with just one.”

I think a lot depends on whether we can find a place off site to work. If the cab can be removed in the way Doug describes there are a couple of major advantages to that, the biggest one being that we can then use volunteers.

Scott: I can supply a crane and a roll-off bin to dispose of the old cab. I can transport the new cab and set it again with the crane when it's done. For Grant purposes, I would estimate $3,500 on my end. That figures a day to remove and a day to install plus the transport. I can handle all the rigging.

Andrew: Unless we find a place to build it offsite, we may have to build it in sections and assemble onsite. Either way, drawings are going to be critical for a fast(er) turnaround

Scott: What are the dimensions of the cab fully assembled? How long would it take to construct the new cab?

Andrew: estimate? 10’x 10’ x 10’

Jeannine: I'm not sure dismantling on site is best, re what Doug said about taking apart, measuring, documenting, which sounds like more than a one-day process. But we are still looking for a location and we don't know how that will work out. I can use that $ figure for grant writing though so that's very helpful, thank you!!

Andrew: as to documenting, I’m not sure what value the current cab is other than for the roof design and the rear windows. A lot of it is 80’s era trex and sheet metal.

Scott: I'll see if I can come up with a place to put it, all of my shops have trucks and equipment in them. I could transport the old cab to whatever site that is and we could dismantle it there.

Jeannine: depends on if anything original is there--side panel, mortises, et cetera, re documentation

Andrew: Mitch and I have woodworking tools but don’t have the space to have the cab onsite

there are a few electrical items (original fuse panel) and whatnot attached inside that should be save and possibly refurbished.

Jeannine: Mitch has a possible lead on a space downtown which would be big enough and excellent for our purposes, he's still waiting to hear so fingers crossed on that

Estimate of hours: We then discussed how many hours of work to rebuild. Andrew estimates “if we had drawings and built it offsite, maybe a month of weekends.” with four to six people building, 8 uninstalling.